Step up to gorgeous wide plank solid wood flooring. Whether you prefer reclaimed wide plank flooring or something more contemporary, we manufacture and install all of your favorite hardwoods in extra-long wide planks for a distinctive look that was once found only in historic homes. The longer lengths of our wide plank solid wood flooring portend a quality and beauty that stands out as a cut above the rest. There is no crisper, cleaner, longer-wearing, more attractive plank floor available.

Adding modern or antique wide plank flooring is one of the most important investments you will make in your home. Though often sacrificed to last minute budgets cuts for common strip-oak flooring or carpet, your flooring shouldn’t be shortchanged.

At WOOD & Co., we specialize in manufacturing and installing quality wide plank flooring in Atlanta, GA. We take pride in delivering the highest quality materials.

We do plank flooring, and we do it right! Call us at 770.514.0129 to get started.

FLOORING SPECIFICS

Standard widths available from 3″ to 8″, with wider boards available in some species and cuts. We commonly provide fixed and random widths, with our most popular being 3,4,5″, 3,5,7″, and 4,6,8″ patterned width. Engineered flooring is available up to 11″ wide.

Standard grades include select, character, and rustic. Antique heart pine and oak flooring are available in fresh-milled faces and original patina. We offer hand-scraped, wire-brushed, beveled-edged and other special treatments.

Wood Species

Plank Flooring Wood Species Choices

We manufacture wide plank flooring in a wide range of f new domestic and imported, and antique wood species. Our flooring is solid 3/4″ thick, end-matched, and kiln dried. Board lengths range from standard nested 7′ bundles, with longer boards available as the species and grade allows. We routinely custom mill for minimum length and to allow for longer maximum lengths, up to 16′ long. (for more options, see Wood Species Selections)

- Alder

- American Cherry

- American Cypress

- Aromatic Cedar

- Ash

- Australian Cypress

- Beech

- Birdseye Maple

- Curly Maple

- Domestic New Heart Pine

- Douglas Fir

- Euro Beech

- Hard Maple

- Hickory

- Locust

- Pecky Cypress

Exotic

- Brazilian Cherry

- Caribbean Heart Pine

- Cumaru (Brazilian Teak)

- Poplar

- Quartered Sawn Red Oak

- Quartered White Oak

- Red Birch

- Red Oak

- Rift & Quartered Red Oak

- Rift & Quartered White Oak

- Rift White Oak

- Walnut (Steamed)

- White Oak

- White Pine

- Wormy Chestnut

- Wormy Maple

- Wormy Red Oak

- Yellow Birch

- Yellow Pine

- IPE (Brazilian Walnut)

- Santos Mahogany

- Sapele

- Tigerwood

Wood Grading

Wood Grading Guide

Nearly all of the wood species that we offer, are available in three different grades. Lower grade offers more of the natural characteristics inherent to the particular species; for higher grades, these characteristics are removed. Antique reclaimed materials are graded differently.

- Select & Better Grade milled from high grade lumber, this grade will have few, if any, knots, mineral streaks, or worm/insect holes. Clear or nearly clear boards. Clear grade is available in some species.

- Character Grade milled from number 1 & 2 common lumber, this grade will have small to medium sound tight knots, some mineral streaks and natural color variations for a wood product with more character.

- Rustic Grade milled to leave in the natural characteristics of the species. This grade will have larger knots, sometimes loose and course. Some knots may have holes, although limited and kept generally smaller than a dime. Worm or insect holes and naturally occurring color variations will be present.

Red Oak Examples

Wood Cuts

Wood Cuts

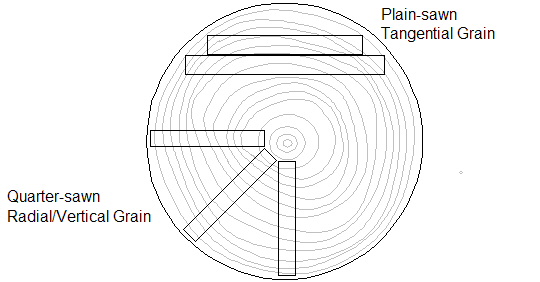

Some of the wood species that we offer, are available in various cuts. For some species, the way in which the wood is positioned relative to its growth rings as its cut from the log, changes the appearance. Oak and ash, for example, have a noticeably different grain pattern–typically finer and more linier grained looking. Quartering oak also brings out the rays in certain species of hardwood–oak, cherry, etc. Rays were the horizontal transports of tree nutrient across the grain. They have an almost holographic appearance in the wood.

- Plain Sawn Lumber is cut across the growth rings in such a way to produce more pronounced grain with flames and cathedral looking characteristics. The growth rings run across the board, as seen in cross-section.

- Quarter Sawn Lumber is cut perpendicular to the growth rings in such a way to produce less pronounced finer looking edge grain, almost a pinstriped effect in some species. The grain is vertical to the faces. The wood is far more stable than plan sawn, especially over radiant heat.

Milling & Other Choices

We specialize in unusual and distinctive flooring, including: pattern floors, old world hand-scraped flooring, circular and radius flooring, rustic wide plank flooring, formal patterns, such as herringbone, inlays, stone and wood combinations, and medallions.

In addition to standard polyurethane finishes, we offer specialized finishes — Tung oil, wax, hand glazing, distressing, cut nails, pegs, and so on. Custom matching stair parts and wood moldings can be milled for nearly all of our species. WOOD & Co. installs only fine hardwood flooring. Our distinctive flooring choices include:

- floor grills – Your floors will look polished and complete with flush-mounted wooden vents, either with and without frames. They can be matched to or contrast with you plank flooring. Vents are installed, sanded, and finished with your floors.

- moldings – No hardwood floor is complete without trim: shoe molding, quarter round, baseboard, etc. Paint-grade (poplar) and matching species moldings are provided for all of our flooring species. Select from our profile catalog.

- paneling – Its hard to beat the warm feel of a wooden room. Sometimes the perfect compliment to a hardwood floor is real hardwood paneling and ceilings. Discover wood paneling for your room.

- stair Parts – Get a perfect match to your floors with our stair treads and rises milled from the same material. Matching cove molding, skirt boards, landing tread, etc. is also available. Shop our stair parts.

- parquetry – herringbone, chevron, and parquetry,

- textured surfaces – many of our plank floors are available with a distinctive surfaces to add to the character. For example, our original patina heart pine is milled from the back side to preserve the existing antique worn face. Hand-scraping create the venerable look and feel of a multi-hundred year-old European floor, when floors were scraped smooth onsite. We offer original patina, rough-sawn, old world hand-scraped flooring and wire brushed surfaces. See patterned flooring.

- pegs & cut nails – We offer wooden pegs that match and pegs that contrast with your plank flooring. We offer 1/2″ and 3/4″ round or square pegs. Optionally, pegs can be pre-installed at the factory in whatever configuration you would like. Square or round pegs in matching or contrasting wood species, and cut nails options,

- edges – standard square edged, or beveled edges (machine or hand cut),

- radius – custom circular and radius flooring and borders,

- inlays – stone and wood combinations, and medallions,

Antique Wood Choices

Antique Wood Choices

We reclaim various venerable old wooden timbers from buildings either deteriorating or slated to be torn down for various reasons. The wood is too valuable to let waste and it is therefore given a new lease on life.

Sometimes it is kept in the original timber or floor decking form, others it is re-milled to produce beautiful flooring, paneling, moldings, stair parts, etc. Many of the original timbers have a beautiful patina developed over hundreds of years. Others have original hand hewing and mortise pockets. Some of our flooring is available with the original patina intact.

Nearly all of the material has insect holes, nail and bolt holes, checking, some cracking, and other characteristics of age. Select grade has few, if any holes. Character and rustic grades have increasingly more holes. Most of all the wood has a mellow coloring and fine grain unavailable from newly cut material. No amount of distressing and staining/glazing can achieve what hundreds of years of age can do.

We routinely work with:

- Antique Heart Pine

- Antique White & Red Oak

- Antique Cypress

- Antique Chestnut

- River-recovered Heart Pine

- River-recovered Cypress

- Original Patina material

- Hand-hewn material

- Rough-sawn material

- Weathered Barn-board

Antique Heart Pine

In the colonial days forests of long-leaf pines stretched from Virginia to Florida. It quickly became the favorite construction material of the colonists. Outraging the early settlers, King George II laid claim to all heart pine over 2 feet in diameter.

Today most large old growth Southern Long-leaf Pine trees have been lumbered. But, it is still available from reclaimed timbers from old mills, barns, houses, factories and warehouses. These timbers yield boards that have developed a beautiful patina over the ages. The old nail holes and other marks left on them from construction add very desirable character. Because of its beauty, limited availability and high demand, heart pine millwork and flooring is an excellent investment.

Specifications

Flooring Specifications

Plank flooring is traditionally made out of a higher grade of lumber than the commodity strip flooring. This allows us to attain the unique widths and lengths we desire in our flooring products. We take pride in delivering the highest quality materials (and installation). We do hardwood plank flooring and we do it right. With experience in serving both residential and commercial sectors, our materials and flooring specialists are the best available. Please take a moment to consider:

- Flooring thickness: 3/4″ unfinished and pre-finished solid wood.

- Length: random, 7′ nested bundles, but up to 16′ is available upon request in some species. just ask!

- Width: random 3″, 4″, and 5″ (standard) up to 8″ in some species. can do all one width. All widths are full face dimensions.

- Lumber: kiln dried to a 6-9% moisture content.

- T&G: all flooring is end-matched (has tongue and groove on all four sides of plank).

- Plowed: all flooring is relief plowed (grooved) on the back for stabilization.

- Waste: common installation of our product generally results in a minimum of waste.

Installers love us for our quality and material dimensions. Homeowner’s love us for the quality and beauty of our floors. Our short boards are often equal to our competition’s longer boards. Thus, creating a more attractive wall or floor with fewer horizontal end joints.

Installation & Finishing

Installation & Finishing

Plank flooring requires slightly more care than narrower strip-width hardwood flooring. Our plank flooring is manufactured from furniture grade lumber, as such, we believe that it should be installed and finished with the same care as a fine piece of furniture.

Wider boards are prone to more noticeable moisture and heat induced expansion and contraction. Thus, extra attention must be taken to minimize wood movement. Your hardwood plank floors should be one of the last items installed and finished prior to moving in your new home.

To ensure success, we recommend the following:

- Building should be weather tight.

- Drywall and painting work should be completed.

- If over concrete, concrete should be fully cured. Check slab and sub-floor moisture content prior to proceeding with work.

- Plywood sub-floors should be dry.

- Sub-floors and stair substructure should be flat, level and true to 1/8″ within a ten-foot radius.

- HVAC should be operational at least 1 week (two weeks is preferable) prior to delivery of materials.

- Flooring should be delivered in advance to allow at least five days (ten day days is preferable) acclimatization prior to installation.

- Normal occupied conditions for temperature, humidity, and ventilation should be maintained before and during the duration of the project.

- Overhead work should be completed prior to initiating flooring installation. No other trades should be working in the areas during floor finishing.

- Floors and stairs should be covered with a breathable material following installation. We recommend no less than 72 hours (five days is preferable) drying time before covering the floors.

- Construction dust should be reduced to acceptable levels during finishing.

- Onsite, environmentally conditioned space should be available to stage flooring.

- We recommend that our plank flooring be installed by blind-nailing over 15# felt for cushion and extra vapor barrier.

- For floorboards over 5″ wide, we recommend that glue be consider along with and blind-nailed. Boards wider than 8″ may require face-nailing or screw-and-plugging to minimize wood movement.

In addition to standard polyurethane finishes, we offer specialized finishes — Tung oil, wax, hand glazing, distressing, cut nails, pegs, and so on. Custom matching stair parts and wood moldings can be milled for nearly all of our species. WOOD & Co. installs only fine hardwood flooring.

Wood Variation

Wood variation

Please Note: We utilize only the highest-grade solid wood raw materials. Wood is a natural product, and as such, has natural variations in appearance, graining, coloration, knots, mineral streaks, etc. The natural beauty of wood lies in the inherent characteristic that no two boards are alike. Mineral streaks may be visible, where the tree has absorbed mineral deposits into the wood. Graining and apparent texture will vary. These natural variations will be present throughout. Variation should be expected. We call your attention to these characteristics of wood because the finished product may vary from pictures, wood samples and showroom displays. The variations are broad, but they constitute the beauty of wood.

Our Warranty

Plank Flooring Warranty Requirements

We stand behind the quality of our products. Should there be any concerns, all questions, issues, or concerns regarding the grading of this product, should be addressed and resolved prior to installation. We can accept no responsibility or liability for the cost of product, replacement and/or labor when the flooring has been installed prior to resolution. Materials cannot be returned for color, texture, pattern or graining unless agreed to prior to delivery. Installing the flooring assumes acceptance of the product.

Check for the following conditions prior to installation: water or excessive moisture under the building, wet sub-floors, or inadequate moisture barrier; the building should be closed in with outside windows and doors in place; gypsum board, plasterwork and painting/staining should be complete; and all concrete, masonry, and framing should be dry.

Moisture and Wood: All flooring materials have been kiln-dried to a moisture content of between 6% and 9% as approved by the National Wood Flooring Association (NWFA). To maintain this moisture content, do not unload in rain, snow or excessively humid conditions. The wider the plank flooring the more critical this becomes. Allow at least four to five days for the flooring to acclimate to the job site. Temperature and humidity should be maintained at or near normal occupancy levels during acclimatization and installation. The NWFA recommends that the HVAC be operational no less than 48 hours prior to the delivery of wood flooring to stabilize interior moisture conditions. Once delivered, flooring should be placed in the rooms where it will be installed to speed up the acclimatization process.

Installation: Plank flooring should be installed over ¾” plywood (OSB is not recommended) sub-floor which has been properly secured to floor joists or concrete substructure. Use of thinner sub-floors is not recommended. There should be no more than 2% to 4% difference in the sub-floor and flooring moisture content. In joist construction, a vapor barrier of 15 pound felt paper should be laid over the plywood. Installation of flooring over concrete, at or below grade, requires a vapor barrier under the slab over the gravel fill and a vapor barrier over the concrete under the plywood. Concrete should be cured for 60 days and tested for moisture prior to installation of flooring. Installation above a crawl space requires use of a 6-8 mil polyethylene ground cover. Proper ventilation, with cross airflow and no dead areas must be provided. Floor must be a minimum of 24″ above the ground. Hardwood flooring is generally not recommended below grade.

Humidity and Temperature: The NWFA recommends that interior conditions be maintained between 30% and 50% humidity, with temperature in the range of 60 to 80 degrees. WOOD & Co. cannot be held liable for moisture-induced movement following installation. Separation between boards, indicating too little moisture/humidity in the building, and cupping or crowning of boards, indicating that there is too much moisture/humidity, are beyond our control. All of our flooring is randomly inspected for moisture content prior to leaving our mill to ensure that it complies with industry standards.

NWFA notes that, “nearly every wood floor endures some separation between boards in winter when buildings are heated and the air is dry. The wood flooring gives up some of its moisture and therefore shrinks. This is normal and acceptable and homeowners should be forewarned of this. Once the heat goes off in the spring, and the indoor environment regains moisture; most of these cracks will close up. Humidifiers are recommended for winter months and use of air conditioning for summer months to maintain proper humidity levels in the home. If separation, cupping, or crowning occur in the floors because of improper humidity levels in the building, it is strongly recommended that one complete heating and cooling cycle take place before making any decisions about repairing/refinishing of the flooring. Any repair work done prior to one complete cycle is counterproductive. In most cases the floors will only repeat the same conditions in a few months. In short, the humidity conditions in the home must be corrected in order for the flooring to have an opportunity to return to at or near it’s original state.”

Care & Maintenance

Care of your Plank Flooring

Properly cared for, your plank floors should last a lifetime and beyond. But, they do require care. Wood is naturally porous and can absorb and release moisture. If the humidity in you home rises, your wood floor will absorb that moisture, causing it to expand. If the humidity falls, your wood floor will release moisture, causing it to shrink.

Your installation should include expansion voids around the perimeter and around columns or floor inserts, plus expansion joints built into the floor surface. These features permit natural, normal expansion and contraction without damage to the floor. Too much moisture causes abnormal expansion, which can lead to cupping, or even buckling of your floor in exceptional situations. In abnormally dry conditions, the wood will contract, leaving separations between floorboards.

Five Steps For Proper Daily Maintenance:

- Sweep the floor daily with a properly treated dust mop. If the floor is used heavily, sweep it up to three times per day.

- Use throw rugs or mats at entranceways to collect grit and dirt that can damage your floors finish.

- Wipe up spills and any moisture on the floor.

- Remove heel marks using an approved floor cleaner applied with a soft cloth or dusting mop.

- Make sure the heating/ventilating/air conditioning system is functioning properly, and set to maintain indoor relative humidity between 30% and 50% year round. In areas of consistently high or low outside humidity, a 15% fluctuation will not adversely affect the wood.

- During wet weather, check for water leakage around doors and windows. Remove debris from expansion voids.

Never Do the Following:

- NEVER shut down the ventilating system in your home for a prolonged period.

- NEVER use household cleaning products or procedures. They can be harmful to the floor finish and to the wood and may leave floors sticky or slippery, and potentially harmful to athletes. We recommend cleaning with vinegar and water at the rate of 3 ounces of vinegar to 1 gallon of water.

- NEVER clean your floor using scrubbing machinery or power scrubbers, which use water under any pressure. Water is your floor’s worst enemy!

- NEVER over wax your floor or use self-polishing Acrylic waxes.

- NEVER walk on the floor with cleats, or high heel shoes.

- NEVER slide furniture on the floors. Always lift heavy items when moving.

Moisture Issues

Moisture and Plank Flooring

With wide plank flooring over 4″ extra care is necessary for good results. Proper acclimation before and maintenance after installation is critical.

All woods are hygroscopic – they absorb moisture when the air is humid, and lose moisture when it’s dry. Wood cells always contain some water. Technically, this moisture content is expressed as a percentage of the weight of the dry wood: 40 to 160 percent in fresh-sawn lumber; 8 to 10 percent (optimum for dimensional stability) in hardwoods kiln-dried for flooring. Wood gains and loses moisture before and after installation, as surrounding environmental conditions fluctuate. As such, it is critical that the inside conditions be maintained to control humidity and temperature to within normal living conditions.

All the wood in your home will contract or expand according to the moisture in the air. In dry, cold weather, cracks and fine lines of separation may appear between boards. If relative humidity and temperature rises, so does the moisture content of hardwood floors. This increase in moisture content can result in the edges of the boards rising as they press against each other from the resultant expansion. This is known as cupping.

Some minor cupping and fine crack separation is to be expected in all hardwood flooring from seasonal changes in humidity. This is normal characteristic of wood. Maintaining consistent humidity and temperature levels will minimize these changes. Floors, as do people, benefit from a balance of humidity and consistent temperature in the home.

Every precaution should be taken to prepare the wood for the environmental conditions of the home prior to installation, and allow for post-installation acclimatization prior to sanding and finishing. Moisture content of the flooring and sub-flooring should be monitored and measured prior to installation. Blind nailing and gluing should be employed with wider boards to minimize wood movement. Vapor barriers should be used were required. Expansion joints and voids should be left under baseboards around the perimeters of rooms.

However, please understand that, we cannot guarantee, with even properly installed hardwood floors, against moisture-induced movement following installation and finishing. Post-installation environmental changes are beyond anyone’s control.

Engineered Wood Flooring

We are proud of our engineered plank flooring. We believe that even engineered wood flooring should look like traditional solid plank flooring. We offer most of our wood species, cuts, and grades in an engineered option. Once installed, you cannot find any difference in appearance or feel underfoot.

Now your below-grade flooring can match the plank flooring in above-grade areas of your home. We also recommend that plank flooring wider than 5″ be engineered for enhanced stability in response to changes in relative humidity.

Due to the design and manufacturing process, engineered wood flooring is a more stable product that enables the use of wider floors. Get the longevity of standard 3⁄4” solid wood flooring with added stability and installation flexibility.

While we offer our engineered plank flooring pre-finished, we prefer the unfinished option to sand and finish on site. The end result is a traditional smooth and seamless floor that has no micro-beveled edges telegraphing that the floor is prefinished.

Our engineered flooring can be installed above and below grade, directly to concrete, and in coastal and otherwise damp or high-humidity climates where solid wood plank tends to cup and move in response to changes in environmental conditions.

W&C engineered plank can blind-nailed, stapled, or glued directly to the sub-floor, and even floated over sub-floors and pads. Please take a moment to consider the following points regarding our engineered plank quality:

- For stability we use multiple layers of wood glued together using cross-grain lamination. The top layer is solid wood in the species selected; the bottom layers are Baltic birch laminated together in an orthogonal fashion.

- The 3/4” thickness allows the floor to walk like solid plank flooring.

- We use the highest grade of quality Russian Birch plywood coupled with our hardwood lamellas to produce a superior performing floor.

- Our two most common thicknesses of Engineered flooring are 3/4″ (5mm wear layer) and 5/8″ (3.8mm wear layer).

- Standard lengths are 1′-10′ with lengths up to 16′ available. Widths are available up to 11″.

- The thick wear-layer allows our engineered plank to be sanded and finished as many times as solid plank flooring.

- Edges are square. Beveled edges are available.

- Tongue & grooved and end-matched like our fine solid plank flooring.

Choices:

- Available unfinished for onsite sanding and finishing, and pre-finished.

- Designed to match traditional plank, our engineered product is available widths range from 3-7”.

- Available in red & white oak, cherry, walnut, ash, hickory, hard maple, Brazilian cherry, heart pine, Cumaru, tigerwood, and Santos mahogany.

- Most species are available in select and character grades. Rustic grade is available in some species.

- Some species are available plain-sawn and quarter-sawn.